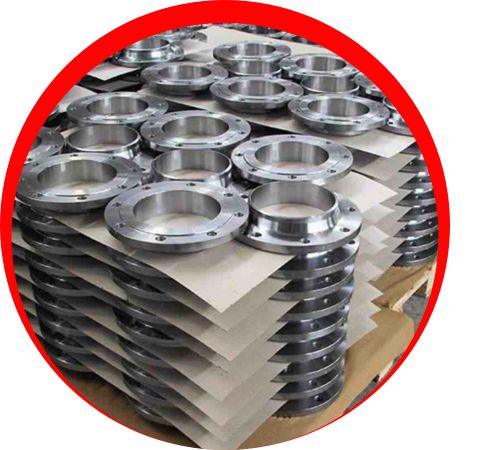

Adrian Nickel Alloys stands out as a top-notch manufacturer and supplier of high-quality **Monel Flanges** in Singapore, Pulau Ujong. These flanges are crafted to be incredibly durable and resistant to corrosion, making them perfect for tough industrial applications. Made from Monel, a nickel-copper alloy, they excel in resisting seawater, acids, alkalis, and other harsh substances, which makes them ideal for extreme environments. Renowned for their toughness and ability to handle high pressure and temperature, Monel Flanges promise a long service life, reliability, and ease of fabrication. Built to meet global standards, they are a trusted choice across various industries for their efficiency and strength in critical operations.

**Monel Flanges** primarily consist of nickel and copper, along with trace amounts of iron, manganese, and other elements that boost their mechanical and corrosion-resistant qualities. This special blend gives them remarkable resistance to stress corrosion cracking, oxidation, and reducing conditions. They boast high tensile strength, excellent toughness, and maintain ductility over a wide temperature range. Plus, Monel Flanges are easy to weld and machine, making them versatile for different industrial needs. Their impressive mechanical strength paired with superior corrosion resistance guarantees consistent and reliable performance in highly aggressive environments.

| Specifications | Monel 400 Flanges |

|---|---|

| Methods Of Forging | Casting Forging Rolling Cutting |

| DIN Standard | PN6/ PN10/ PN16/ PN25/ PN40/ PN64 |

| Equipment | Pushing Machine Press machine electric bevelling machine |

| Class | Class 150 to 2500. PN 2.5 to PN 250. |

| Use In | Marine & dredging Sanitation Process Instrumentation Oil and Gas Petrochemical/ Refinery/Chemical Power etc. |

| Manufacturing Productivity | 600 ton per month |

| JIS Standard | 5K/ 10K/ 16K 20K/ 30K/ 40K/ 63K |

| Size | 1/2” to 24” (customized diameters: up to 60”.) |

| Face Type | RF (Raised Face), RTJ (Ring Type Joint) |

| EN Standard | 6Bar/ 10Bar/ 16Bar/ 25Bar/ 40Bar |

| Supporting Material For Flanges | Gasket/ Ring Joint/ Flanges Bolts |

| Testing | Hydrostatic testing machine Magnetic particle detector Direct-reading Spectrograph UI trasonic flaw detector |

| Grade | C | Mn | Si | Cu | S | Ti | Ni | Al | Fe |

| Monel 400 | 0.3 max | 2.0 max | 0.5 max | 28.0 – 34.0 | 0.02 max | – | 63.0 min | 0.50 max | 1.0 – 2.5 |

| Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2” % |

|---|---|---|---|

| 70 | 110,600 | 54,900 | 44 |

| 1000 | 89,000 | 35,600 | 49 |

| 1200 | 83,000 | 35,400 | 54 |

| 1400 | 67,000 | 34,400 | 53 |

| 1600 | 45,000 | 28,200 | 58 |

At Adrian Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Monel Flanges in Pulau ujong, Singapore , providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Pulau ujong, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

**Monel Flanges** find their place in various sectors, including marine, chemical, oil and gas, power generation, and petrochemicals. Their outstanding resistance to seawater makes them perfect for offshore platforms, shipbuilding, and marine equipment. In chemical processing plants, they are the go-to choice for handling acids, alkalis, and corrosive fluids. You’ll also see them in piping systems, heat exchangers, condensers, and valves where strength and corrosion resistance are crucial. With their durability, toughness, and ability to endure extreme conditions, Monel Flanges are a reliable option for industries looking for long-lasting solutions.