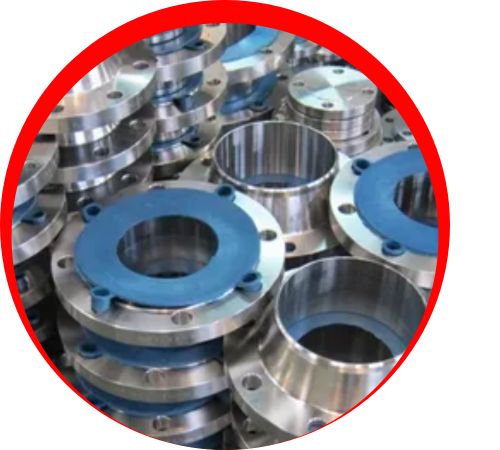

Adrian Nickel Alloys, based in Pulau Ujong, Singapore, stands out as a premier manufacturer and supplier of top-notch Hastelloy flanges. With a focus on corrosion-resistant materials, the company provides an extensive selection of Hastelloy flanges that are engineered for exceptional performance in harsh environments. These flanges find their place in various industries, including chemical processing, marine, oil & gas, and power generation. Adrian Nickel Alloys produces flanges in multiple types—such as weld neck, slip-on, blind, and threaded—ensuring they meet global piping standards. Renowned for their precision engineering and rigorous quality control, the company has earned a reputation as a reliable partner for critical applications both locally and internationally.

The Hastelloy flanges crafted in Pulau Ujong, Singapore, are made from nickel-molybdenum and nickel-chromium-molybdenum alloys like Hastelloy C22, C276, and C2000. These alloys are known for their outstanding resistance to strong oxidizers, acids, and chlorides, making them perfect for challenging chemical environments. Hastelloy flanges boast impressive mechanical strength, with tensile strengths often surpassing 690 MPa, and they show remarkable resistance to pitting, crevice corrosion, and stress-corrosion cracking. These flanges maintain their integrity even under high pressure and temperature conditions, making them ideal for applications that involve thermal cycling and corrosive media.

| Specifications | Hastelloy Flanges |

|---|---|

| ASME B16.5 Hastelloy C276 Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Hastelloy Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Hastelloy C276 Flange Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Hastelloy C276 Flange Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Hastelloy C276 Flange Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Hastelloy C276 Flange Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Hastelloy C276 Flange Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Hastelloy C276 Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Hastelloy C276 Flanges |

|

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations Hastelloy C276 Threaded Flange, Socketweld Flange, Slip-On Flange, Blind Flange, Weld Neck Flange |

| Grade | Hastelloy C22 |

|---|---|

| C | 0.010 max |

| Mn | 0.50 max |

| Si | 0.08 max |

| S | 0.02 max |

| Co | 2.50 max |

| Ni | 50.015 min |

| Cr | 20.00 – 22.50 |

| Fe | 2.00 – 6.00 |

| Mo | 12.50 – 14.50 |

| P | 0.02 max |

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52000 , MPa – 355 |

| Elongation | 40 % |

Hastelloy flanges produced in Pulau Ujong, Singapore, are widely utilized in industries that require exceptional corrosion resistance and mechanical reliability. Common applications include chemical reactors, heat exchangers, acid processing systems, offshore platforms, and pollution control equipment. These flanges ensure secure, leak-proof connections in piping systems that are subjected to harsh chemical and thermal conditions. Their durability minimizes maintenance needs and guarantees long-term operational efficiency.

Contact us to get a quick quote for your requirement.

Hastelloy flanges are widely used in industries requiring high performance in extreme conditions. They are ideal for petrochemical processing, aerospace applications, and marine environments due to their superior corrosion resistance and strength. These flanges are also utilized in chemical processing plants, power generation, and oil and gas industries, where durability and reliability are essential. Their ability to withstand high temperatures and aggressive chemicals makes them a valuable component in critical systems and high-stress applications.